|

Size: 8324

Comment:

|

Size: 8357

Comment:

|

| Deletions are marked like this. | Additions are marked like this. |

| Line 20: | Line 20: |

| || property || Si || !SiO2 || !Si3N4 || !GaAs || Cu || Al || Ag || Au || Ta || ITO || Kovar || Invar || || Density g/cm^3 || 2.33 || 2.65 || 3.20 || 5.32 || 8.96 || 2.7 || 10.5 || 19.3 || 16.7 || 6.43 || 7.85 || 8.05 || || Coefficient of Thermal Expansion 10-6/K || 2.6 || 0.5 || 3.2 || 5.7 || 16.5 || 23.1 ||18.9 || 14.2 || 6.3 || 10? || 5.3 || 1.3 || || Heat Capacity J/g-K || 0.71 || 0.74 || 0.71 || 0.33 || 0.38 || 0.90 || 0.24 || 0.13 || 0.14 || || 0.44 || 0.51 || || ''Heat Capacity MJ/m^3^-K'' || 1.65 || 1.96 || 2.27 || 1.76 || 3.40 || 2.43 || 2.47 || 2.49 || 2.34 || || 3.45 || 4.11 || || Thermal Conductivity W/m-K || 149 || 1 || 30 || 55 || 401 || 237 || 430 || 320 || 58 || || 17.3 || 10.1 || || ''density normalized thermal conductivity'' || 64 || 0.4 || 9.4 || 10 || 45 || 88 || 41 || 16 || 3.5 || || 2.5 || 12 || || ''Thermal Diffusivity mm^2^/s'' || 90 || 0.5 || 13 || 31 || 118 || 98 || 174 || 129 || 25 || || 5 || 2.5 || || Youngs Modulus GPa || 150 || 73 || 260 || 86 || 110 || 70 || 83 || 78 || 186 || 116 || 140 || 148 || || Tensile Strength MPa || 7000 || 50 || 70 || 57 || 210 || 40 || 170 || 100 || 200 || 120 || 270 || 680 || || ''Atomic Weight (avg/atom)'' || 28 || 20 || 20 || 72.3 || 63.5 || 27 || 108 || 197 || 181 || 56.7 || 57.2 || 56.3 || || Resistivity nano-ohm-m || - || - || - || - || 17 || 27 || 16 || 22 || 131 || 2200 || 490 || 820 || || Dielectric Constant || 11.8 || 3.9 || 7.5 || 12.9 || - || - || - || - || - || - || - || - || |

|| property || Si || !SiO2 || !Si3N4 || !GaAs || Cu || Al || Ag || Au || Ta || ITO || Kovar || Invar || || Density g/cm^3 || 2.33 || 2.65 || 3.20 || 5.32 || 8.96 || 2.7 || 10.5 || 19.3 || 16.7 || 6.43|| 7.85 || 8.05 || || Coefficient of Thermal Expansion 10-6/K || 2.6 || 0.5 || 3.2 || 5.7 || 16.5 || 23.1 || 18.9 || 14.2 || 6.3 || 10? || 5.3 || 1.3 || || Heat Capacity J/g-K || 0.71 || 0.74 || 0.71 || 0.33 || 0.38 || 0.90 || 0.24 || 0.13 || 0.14 || - || 0.44 || 0.51 || || ''Heat Capacity MJ/m^3^-K'' || 1.65 || 1.96 || 2.27 || 1.76 || 3.40 || 2.43 || 2.47 || 2.49 || 2.34 || - || 3.45 || 4.11 || || Thermal Conductivity W/m-K || 149 || 1 || 30 || 55 || 401 || 237 || 430 || 320 || 58 || - || 17.3 || 10.1 || || ''density normalized thermal conductivity'' || 64 || 0.4 || 9.4 || 10 || 45 || 88 || 41 || 16 || 3.5 || - || 2.5 || 12 || || ''Thermal Diffusivity mm^2^/s'' || 90 || 0.5 || 13 || 31 || 118 || 98 || 174 || 129 || 25 || - || 5 || 2.5 || || Youngs Modulus GPa || 150 || 73 || 260 || 86 || 110 || 70 || 83 || 78 || 186 || 116 || 140 || 148 || || ''speed of sound km/s'' || 8.0 || 5.2 || 9.0 || 4.0 || 3.5 || 5.1 || 2.8 || 2.0 || 3.3 || 4.2 || 4.2 || 4.3 || || Tensile Strength MPa || 7000 || 50 || 70 || 57 || 210 || 40 || 170 || 100 || 200 || 120 || 270 || 680 || || ''Atomic Weight (avg/atom)'' || 28 || 20 || 20 || 72 || 64 || 27 || 108 || 197 || 181 || 57 || 57 || 56 || || Resistivity nano-ohm-m || - || - || - || - || 17 || 27 || 16 || 22 || 131 || 2200 || 490 || 820 || || Dielectric Constant || 11.8 || 3.9 || 7.5 || 12.9 || - || - || - || - || - || - || - || - || |

| Line 35: | Line 36: |

| The vast bulk of the material , and the largest pieces of of the server-sat, will be silicon. Since the server-sat undergoes wide temperature changes when it passes in and out of shadow, or undegoes thermal annealing, it will be more survivable if the non-silicon portions are made of composite materials that match silicon's 2.6E-6/Kelvin coefficient of thermal expansion (CTE). For example, Zicar Ceramics SALI-2 (search on Matweb]] is a mixture of 80% alumina, 20% silica with a a CTE of 6.2E-6 . Combined in different proportions with silica ( !SiO2 ) , it might be nicely matched to silicon. | The vast bulk of the material , and the largest pieces of of the server-sat, will be silicon. Since the server-sat undergoes wide temperature changes when it passes in and out of shadow, or undegoes thermal annealing, it will be more survivable if the non-silicon portions are made of composite materials that match silicon's 2.6E-6/Kelvin coefficient of thermal expansion (CTE). For example, Zicar Ceramics SALI-2 (search on Matweb]] is a mixture of 80% alumina, 20% silica with a a CTE of 6.2E-6 . Alumina, combined in different proportions with silica ( !SiO2 ) , might be nicely matched to silicon. |

| Line 37: | Line 38: |

| Server sats will also need transparent materials and conductors that closely match silicon. The metals have very high CTEs, while !Si02 has a very low CTE, so slotted metal wires with !SiO2 in the gaps is one way to make a "material" that is both conductive and has the same CTE as silicon. | Server sats will also need transparent materials and conductors that closely match silicon. The metals have very high CTEs, while !SiO2 has a very low CTE, so slotted metal wires with !SiO2 in the gaps is one way to make a "material" that is both conductive and has the same CTE as silicon. |

| Line 40: | Line 41: |

| '''Volunteer Opportunities''' <<BR>>Look for compounds and composite materials that closely match silicon.<<BR>>Find properties for isotopically pure silicon; it has 60% better thermal conductivity, it gets much better at lower temperatures, and it is getting cheap enough to use in chips. It may be the best material for heat spreaders }}} | '''Volunteer Opportunities''' <<BR>>(1) Look for compounds and composite materials that closely match silicon.<<BR>>(2) Find properties for isotopically pure silicon; it allegedly has 60% better thermal conductivity, it gets much better at lower temperatures, and it is getting cheap enough to use in chips. It may be the best material for heat spreaders }}} |

Manufacturing Server Sky

Devices and materials

A lot can be done on a very thin planar surface. Other things cannot be done easily. Here are some common electronic devices:

Thin Planar |

Non-planar |

Printed circuit laminates (ultrathin) |

Connectors |

Resistors |

cooling fins |

Planar Capacitors |

Wound foil capacitors |

pixel sensor arrays |

lenses |

liquid crystal light modulators |

LEDs (?) |

Striplines |

Coax |

Microwave-frequency inductors |

Low frequency inductors and transformers |

surface acoustic wave (SAW) resonators |

crystals |

beam lead interconnect |

wirebonds and solderbumps |

Silicon is the construction material of choice - the solar cell is made of silicon, and the processors and memory are also. Here are some relevant properties of silicon, SiO2 glass, gallium arsenide, copper, aluminum, silver, gold, tantalum, indium tin oxide, kovar, and invar, which will make up 99.9% of the weight of a server-sat:

property |

Si |

SiO2 |

Si3N4 |

GaAs |

Cu |

Al |

Ag |

Au |

Ta |

ITO |

Kovar |

Invar |

Density g/cm^3 |

2.33 |

2.65 |

3.20 |

5.32 |

8.96 |

2.7 |

10.5 |

19.3 |

16.7 |

6.43 |

7.85 |

8.05 |

Coefficient of Thermal Expansion 10-6/K |

2.6 |

0.5 |

3.2 |

5.7 |

16.5 |

23.1 |

18.9 |

14.2 |

6.3 |

10? |

5.3 |

1.3 |

Heat Capacity J/g-K |

0.71 |

0.74 |

0.71 |

0.33 |

0.38 |

0.90 |

0.24 |

0.13 |

0.14 |

- |

0.44 |

0.51 |

Heat Capacity MJ/m3-K |

1.65 |

1.96 |

2.27 |

1.76 |

3.40 |

2.43 |

2.47 |

2.49 |

2.34 |

- |

3.45 |

4.11 |

Thermal Conductivity W/m-K |

149 |

1 |

30 |

55 |

401 |

237 |

430 |

320 |

58 |

- |

17.3 |

10.1 |

density normalized thermal conductivity |

64 |

0.4 |

9.4 |

10 |

45 |

88 |

41 |

16 |

3.5 |

- |

2.5 |

12 |

Thermal Diffusivity mm2/s |

90 |

0.5 |

13 |

31 |

118 |

98 |

174 |

129 |

25 |

- |

5 |

2.5 |

Youngs Modulus GPa |

150 |

73 |

260 |

86 |

110 |

70 |

83 |

78 |

186 |

116 |

140 |

148 |

speed of sound km/s |

8.0 |

5.2 |

9.0 |

4.0 |

3.5 |

5.1 |

2.8 |

2.0 |

3.3 |

4.2 |

4.2 |

4.3 |

Tensile Strength MPa |

7000 |

50 |

70 |

57 |

210 |

40 |

170 |

100 |

200 |

120 |

270 |

680 |

Atomic Weight (avg/atom) |

28 |

20 |

20 |

72 |

64 |

27 |

108 |

197 |

181 |

57 |

57 |

56 |

Resistivity nano-ohm-m |

- |

- |

- |

- |

17 |

27 |

16 |

22 |

131 |

2200 |

490 |

820 |

Dielectric Constant |

11.8 |

3.9 |

7.5 |

12.9 |

- |

- |

- |

- |

- |

- |

- |

- |

Data mostly from wikipedia and various places online. See also Matweb the material properties website, B.Y.U. CTE table. Tensile strength untrustworthy, and many parameters are anisotropic. Use only for rough estimates.

The vast bulk of the material , and the largest pieces of of the server-sat, will be silicon. Since the server-sat undergoes wide temperature changes when it passes in and out of shadow, or undegoes thermal annealing, it will be more survivable if the non-silicon portions are made of composite materials that match silicon's 2.6E-6/Kelvin coefficient of thermal expansion (CTE). For example, Zicar Ceramics SALI-2 (search on Matweb]] is a mixture of 80% alumina, 20% silica with a a CTE of 6.2E-6 . Alumina, combined in different proportions with silica ( SiO2 ) , might be nicely matched to silicon.

Server sats will also need transparent materials and conductors that closely match silicon. The metals have very high CTEs, while SiO2 has a very low CTE, so slotted metal wires with SiO2 in the gaps is one way to make a "material" that is both conductive and has the same CTE as silicon.

Volunteer Opportunities

(1) Look for compounds and composite materials that closely match silicon.

(2) Find properties for isotopically pure silicon; it allegedly has 60% better thermal conductivity, it gets much better at lower temperatures, and it is getting cheap enough to use in chips. It may be the best material for heat spreaders

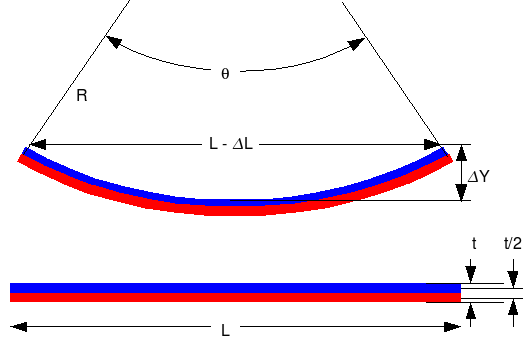

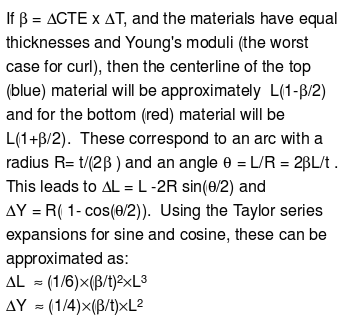

Curling can occur if the front and back sides of a server-sat (especially the solar cell) have different CTEs, and the server-sat undergoes repeated thermal cyclings. There is nothing inherent in a server-sat that establishes "flat" - it will flex until tensions and compressions are minimized. A slightly curved server-sat is not a severe operational problem. If the edges are turned up a few degrees, that will reduce collected solar energy very little. The main problem is the effect on the phasing of the radios. Significant curling will change the spacing of the radios at opposite sides of the curl, and lift them above the plane of the radios at the center of the curl. Without some means of determining precisely how much curl is there, the radios may be in incorrect phases.

|

|

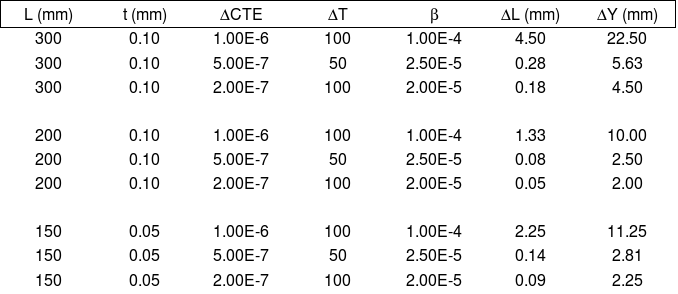

Here are some curls for various temperature and CTE changes and sizes:

MORE LATER

Factories

Much of the manufacturing for Server Sky can happen in Washington County, Oregon, around Hillsboro.

The main component by weight is the solar cell. The Solar World plant in Hillsboro is the largest solar cell manufacturer in the US - certainly the most highly automated. The solar cells in their illustrations look like 100 millimeter diameter, but perhaps they can learn to make larger ones.

The most complicated components are the microprocessors. Some version of the Intel Atom may be suitable. For a server-sat, it is preferable to use a fast, deep submicron, 1V processor with heavy doping (less sensitive to radiation damage) and at least an epi substrate. A trench isolated SOI process is preferred. AMD processors are all trench isolated SOI. Intel's Penryn process, with thick Hafnium oxide gates and work-function controlled gate metalization, will also be more radiation resistant. Over time, most process improvements desirable for high performance processors will also be desirable for radiation hardness.

The most radiation sensitive components are likely to be the flash memory. These incorporate error correction, but software error correction and frequent rewrites may be necessary to correct for radiation induced charges.

The gallium arsenide radios will probably be made by Triquint.

The LCD material will be pretty simple. It will need to survive freezing, and the LCDs should be divided into separately-addressed cm-sized cells so that meteorite punctures will not disable a whole LCD. That said, they only need to switch very slowly, and consequently have wide flexibility in operating voltage. They will probably be constructed from a 1 micron layer of LCD material between two pieces of indium oxide coated 30 micron thick glass (which is commercially available). This is standard technology, and has been manufactured locally by startups such as Sarif and Steridian, and is currently manufactured by Sharp in Vancouver, Washington.

Washington county companies such as D.W. Fritz build wafer handling equipment .

MORE LATER