|

Size: 2475

Comment:

|

Size: 2476

Comment:

|

| Deletions are marked like this. | Additions are marked like this. |

| Line 1: | Line 1: |

| #format jsmat | #format jsmath |

Making Ballast from Rocket Tanks with Lasers

Space debris may be an opportunity, not a problem. Rocket tanks may be cut into gram-sized weights with lasers, then added to ultra-thinsats to stabilize their orbits against light pressure. Perhaps, with some technological advances, we can learn to build solid state lasers that don't need optics, and mount them on thinsats. A 100 milliwatt (average) pulsed laser will not cut metal very fast, but in time it will cut it.

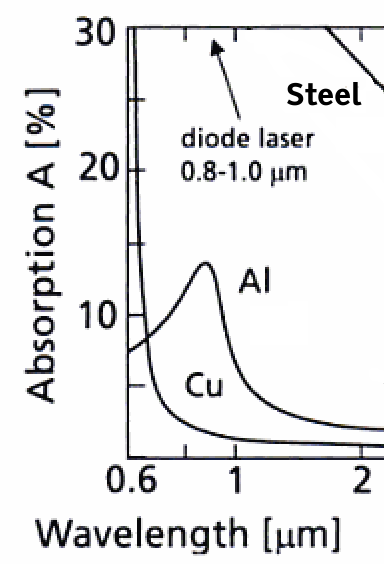

Rocket upper stage tanks have a thickness from 1 to 5 mm (Need Reference) and are typically aluminum alloy. Aluminum has an absorption peak of 14% around 900nm (LOOSEN1998). If we assume a 1cm2 aperture emitter and a 1 meter distance, we can make a 10&um;m spot, maybe, given a magic phase-coherent focusing laser.

Loosen's equation 2 offers Treusch's formula for beam-center intensity:

I_v \propto { { T_v \kappa } \over { Abs w_F arctan left( { 8 \kappa t_L } \over { w_f^2 } right)^2

|| || Aluminum ||

I_v |

|

Threshold Intensity |

T_v |

3000K |

Vaporization Temperature |

w_f |

10μm |

spot radius |

Abs |

0.14 |

Absorptioncoefficient |

\kappa |

1e-4 m2/s |

Thermal diffusivity, \kappa = \lambda_th / \rho c_h |

\lambda_th |

240 W/m-K |

Thermal conductivity |

\rho |

2700 kg/m3 |

Density |

c_h |

900 J / kg-K |

Heat capacity |

For a 1&um;s pulse, a 10&um;m kerf, and a 10 watt pulse (10MW/cm2),

(LOOSEN1998) Peter Loosen, Lasers in Materials Processing, figure 6 on page 291 in ''Advances in Lasers and Applications'' 1998. |