Making Ballast from Rocket Tanks with Lasers

Space debris may be an opportunity, not a problem. Rocket tanks may be cut into gram-sized weights with lasers, then added to ultra-thinsats to stabilize their orbits against light pressure. Perhaps, with some technological advances, we can learn to build solid state lasers that don't need optics, and mount them on thinsats. A 100 milliwatt (average) pulsed laser will not cut metal very fast, but in time it will cut it.

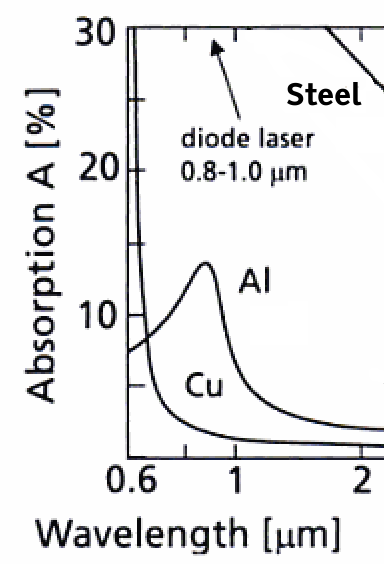

Rocket upper stage tanks have a thickness from 1 to 5 mm (Need Reference) and are typically aluminum alloy. Aluminum has an absorption peak of 14% around 900nm (LOOSEN1998).

(LOOSEN1998) Peter Loosen, Lasers in Materials Processing, figure 6 on page 291 in ''Advances in Lasers and Applications'' 1998. |

|